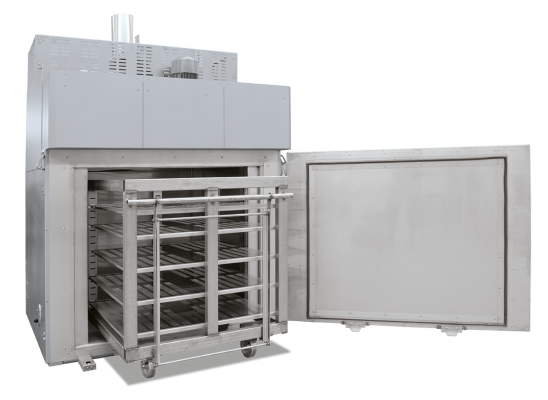

Chamber Ovens up to 260 °C

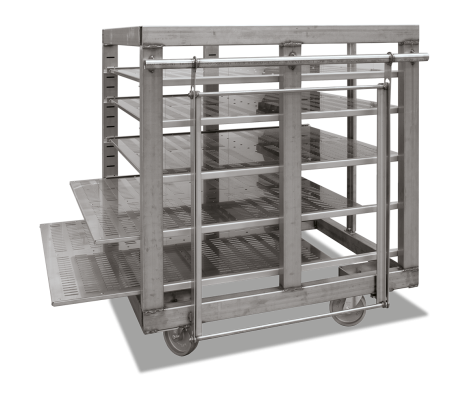

he chamber ovens of the KTR range can be used for complex drying processes and heat treatment of charges to an application temperature of 260 °C. The high-performance air circulation enables optimum temperature uniformity throughout the work space. A wide range of accessories allow the chamber ovens to be modified to meet specific process requirements.

Standard Equipment

- Tmax 260 °C

- Electrically heated (via a heating register with integrated chrome steel heating elements) or gas-fired (direct or indirect gas-fired including injection of the hot air into the intake duct)

- Temperature uniformity up to +/− 3 °C according to DIN 17052-1 (for design wihout track cutouts)

- High-quality mineral wool insulation provides for outer temperatures of < 25 °C above room temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- High air exchange for fast drying processes

- Double-wing door for furnaces KTR 2300 and larger

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Controller with touch operation B500 (5 prgrams with each 4 segments)

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

Reviews

There are no reviews yet.